Leverage Scale,

Expertise and Speed

Driving efficiency and cost-effectiveness with injection molding services

Flexible and customizable services for volume production

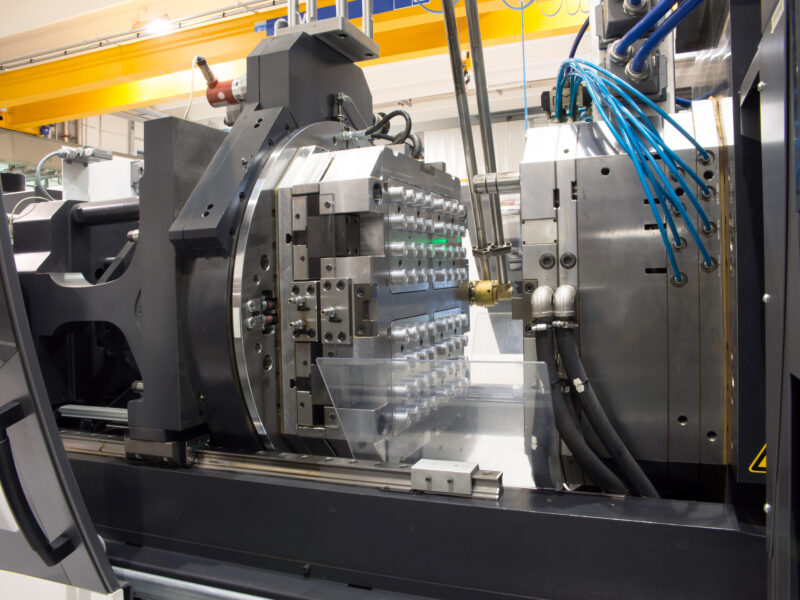

Injection mold presses from seven to 4,500 tons

Specialty molding for

challenging applications

Class 7 and Class 8 clean room environments

We provide customizable molding services to ensure you meet your product launch goals. From mold testing to short production runs, SyBridge gives you the firepower to get your injection molding production rolling.

Customizable Molding Services

SyBridge provides resources and expertise for each stage of your product development.

We offer supportive molding services, including:

- Prototyping

- Functional Mold Testing

- Mold Qualification

- Bridge to Production Molding

Specialty Molding

Our molding services leverage deep expertise and decades of experience utilizing the latest advances in scientific molding for an array of molding methods, including:

- High-Cavitation Molding

- Multi-Shot Molding

- Micro Molding

- Insert Molding

- Overmolding

- In-Mold Closing

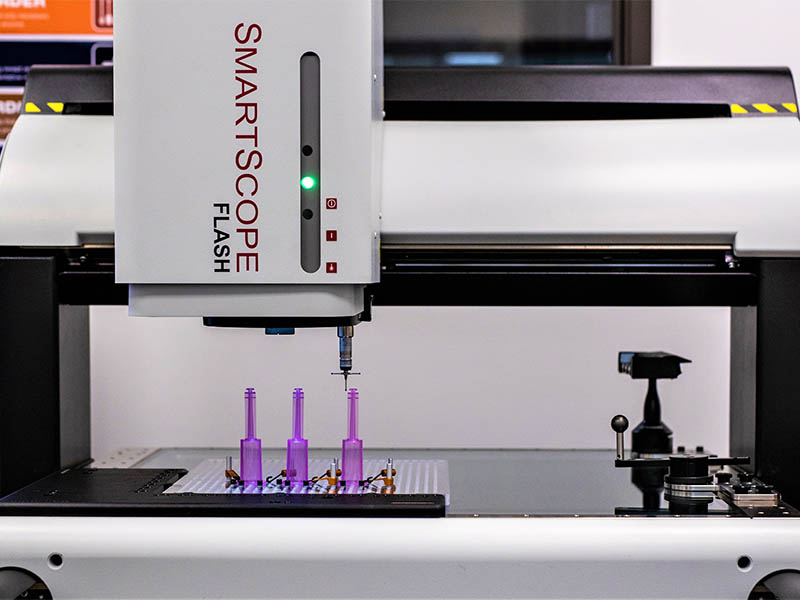

Mold Testing

Mold testing and verification includes the mold, hot runner system and associated temperature/pressure control monitor systems with the specified resin. Our expertise in resins ranges from general purpose and engineering-grade to specialty resins.

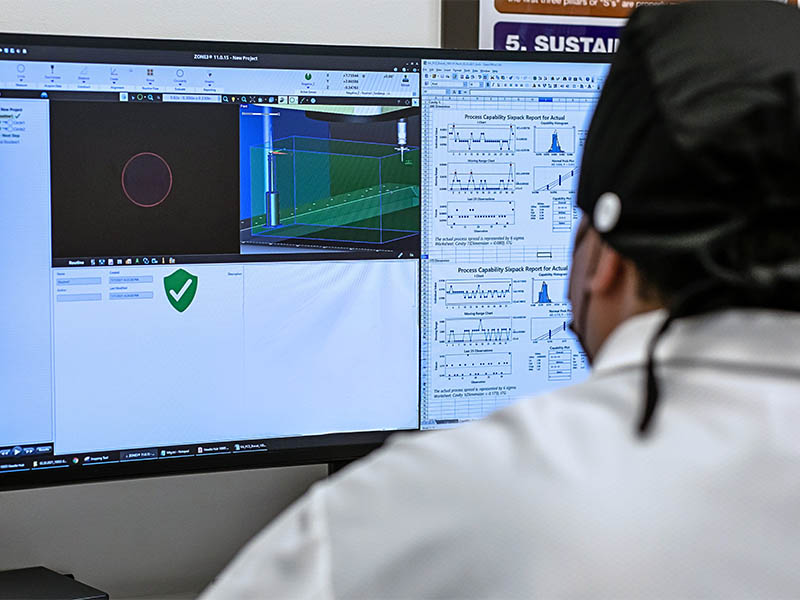

Mold Qualification

We conduct mold qualification to establish optimal processing parameters.

Our six-step process development analysis includes:

- Viscosity Curve

- Cavity Balance Study

- Pressure Drop Study

- Cosmetic Process Window Study

- Gate Seal Study

- Cooling Time Study

Utilizing applied statistics and Design of Experiments (DOE) studies, we further optimize process parameters and cycle times to drive efficiency.

Validation Reporting

Industry-specific protocols include process qualification studies to validate product specifications and quality criteria. Validation reports and all necessary documentation, including procedures and certifications, are provided for compliance.

Our validation services include:

- IQ/OQ/PQ for Medical/Life Sciences

- Pre-Production Approval (PPA) for Mobility/Aerospace

- Customer-Defined Validation Protocol